Additive Manufacturing

High strength, end use parts, in a matter of hours - that's now a reality thanks to Bremar's range of in-house Markforged industrial 3D printers.

We help companies of all sizes to implement the latest additive manufacturing technologies and processes in their business without the significant up-front investment. We've made that investment ourselves so you don't have to.

Well beyond the realms of traditional "rapid prototyping", our additive manufacturing equipment is capable of producing strong, functional, end use parts, when you need them.

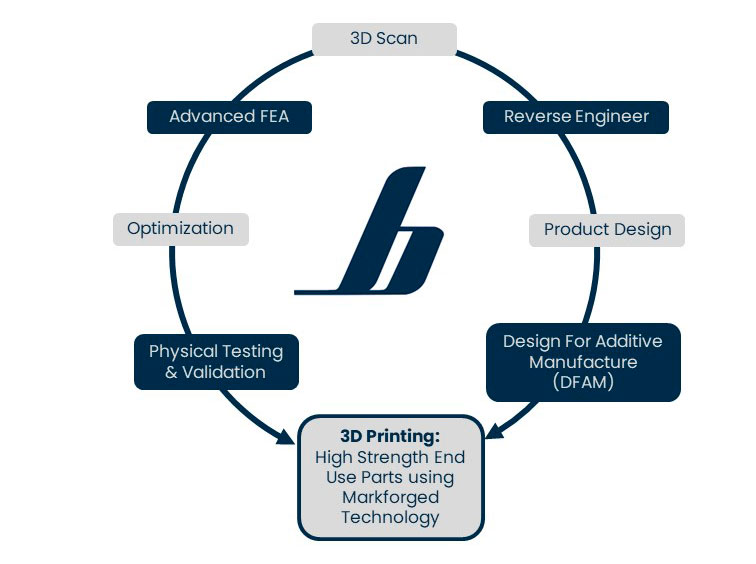

The Bremar Difference

More than just a 3D print bureau, Bremar has the tools and experience to design, optimize, engineer & manufacture turnkey solutions to get your products to market faster than ever before.

Whether it's reverse engineering a broken or obsolete part to get you back up and running ASAP, modifying an existing component to suit the additive manufacturing process, or designing a completely new product with additive in mind from the very start, our team of experienced engineers can provide you with a true end to end solution.

Complementing Traditional Manufacturing

And it's not just the part itself that can be made using this technology... traditional manufacturing processes can be greatly enhanced using 3D printed tooling, jigs, welding fixtures, special service tools, press tools, molds, soft jaws, robotic end effectors, and more.

This means you can keep your skilled staff and production machinery focussed on revenue generating activities, rather than spending time creating tools to do the job.

Our Markforged Range

Bremar's range of Markforged 3D printers enables us to tackle a wide variety of projects with composite print bed sizes ranging from 320x130x160mm right up to 525x400x400mm on our flagship FX20, while our Metal X system allows for accurate printing of small and medium sized metal parts.

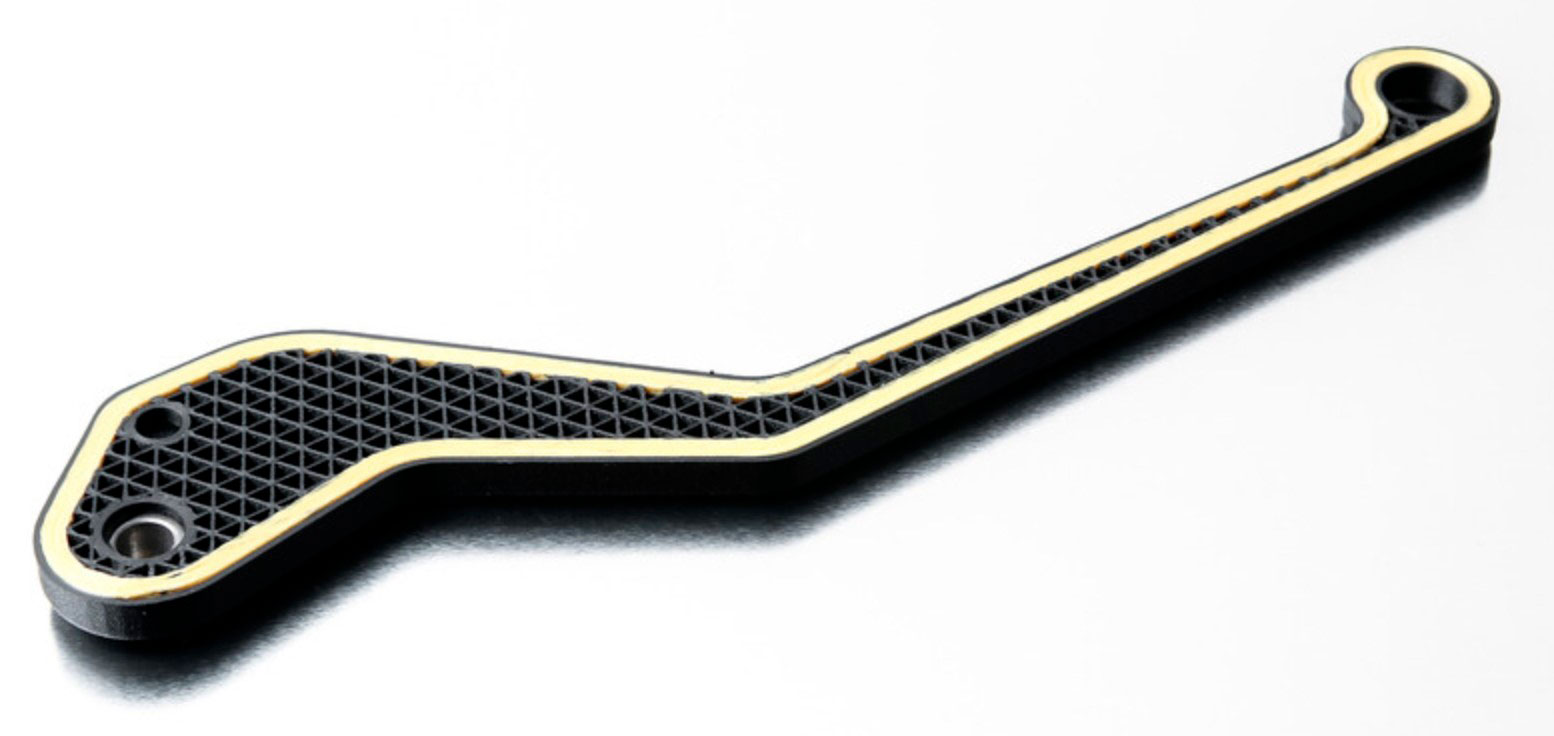

Engineered Materials

Industrial grade materials are further enhanced by Markforged's unique Continuous Fiber Reinforcement (CFR) process, where a continuous strand of fiber is inlaid within the part to reinforce the perimeter, selected features or entire layers of the part, resulting in composite parts that are as strong and stiff as aluminium

Add to this a further array of specialised materials such as TPU for flexible parts, Ultem for high temperature applications, and a range of metals including Stainless Steel, Inconel, Copper & Tool Steels, and the possibilities to solve your manufacturing challenges are endless.

Get In Touch

We're here to help you get the most out of this technology and implement it in your business now. Contact us to discuss how additive manufacturing can generate real results and real savings today.